About us

My name is Sylwester Jabłoński and I am the founder and owner of Parkiety Jabłoński.

In our family, the love for wood has been passed down from generation to generation for over 140 years. This passion inspired me to set up a company specializing in creating solid floors from the noblest species of wood.

For over 30 years of operation, we have been constantly developing our products and combining our experience with modern trends, responding to the needs of even the most demanding customers. Taking care of the environment, our goal is to promote sustainable, natural and durable products that will provide the interiors of our customers with the peace and warmth of nature for years to come.

We invariably focus on the highest quality and innovation, as evidenced by the path we have traveled together with the entire team over the last three decades. However, we do not stand still and boldly plan the next steps on the path of our development.

The company's history

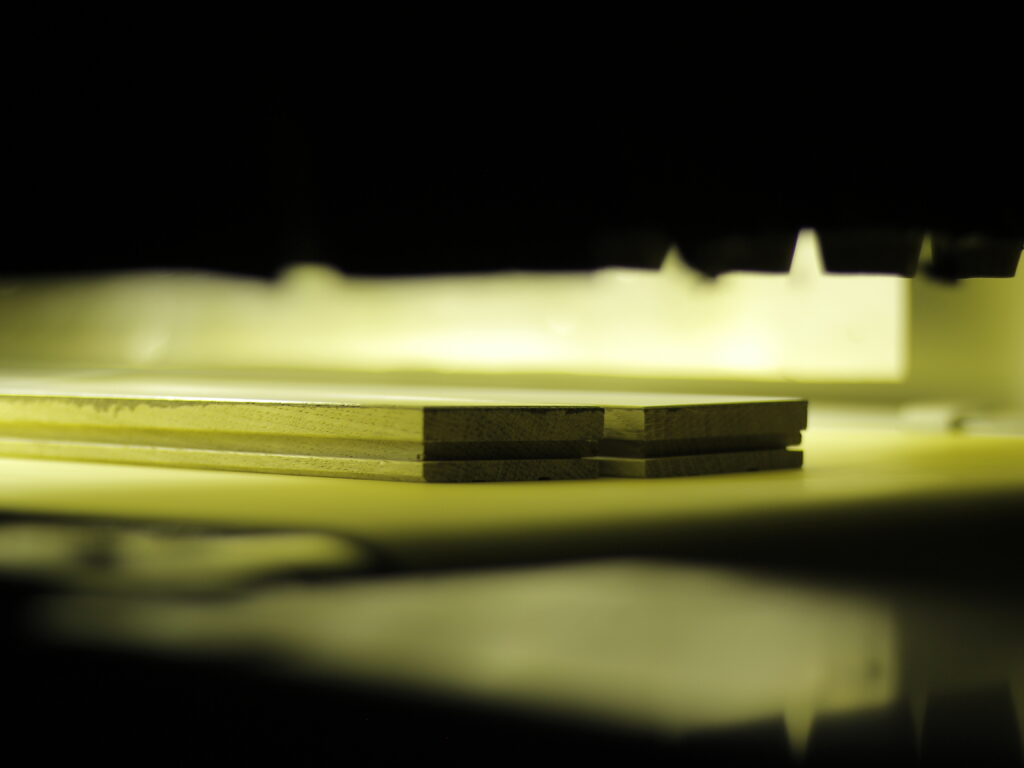

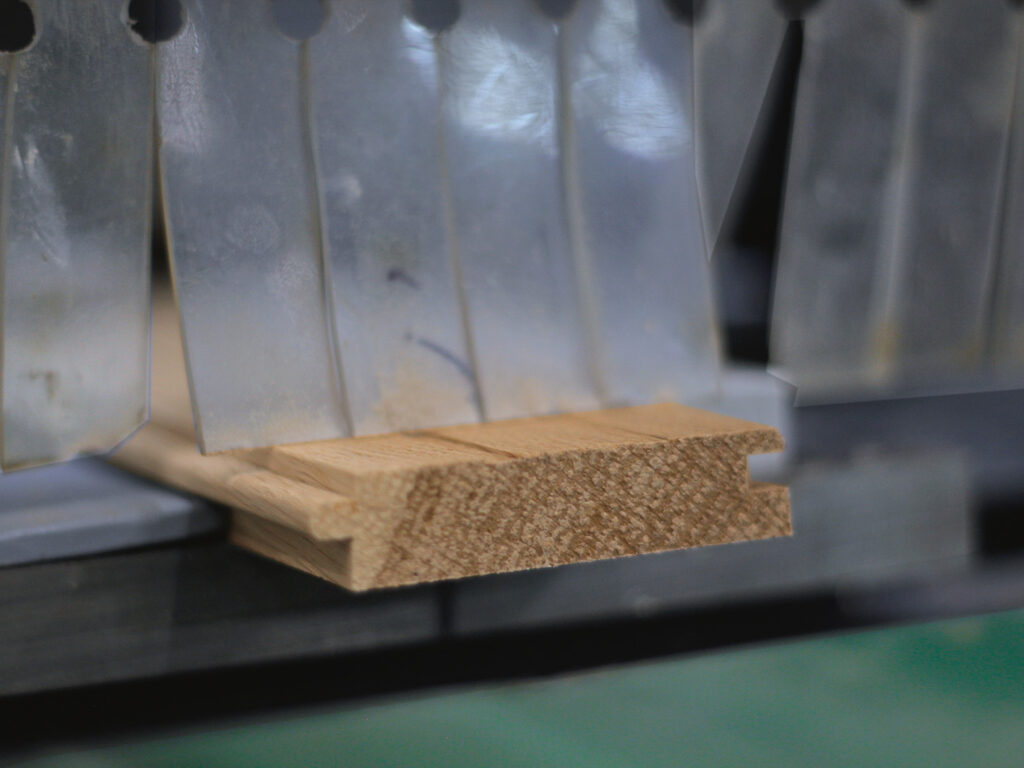

From the beginning, our floors were produced not from semi-finished products, but from round wood brought straight from the forest.

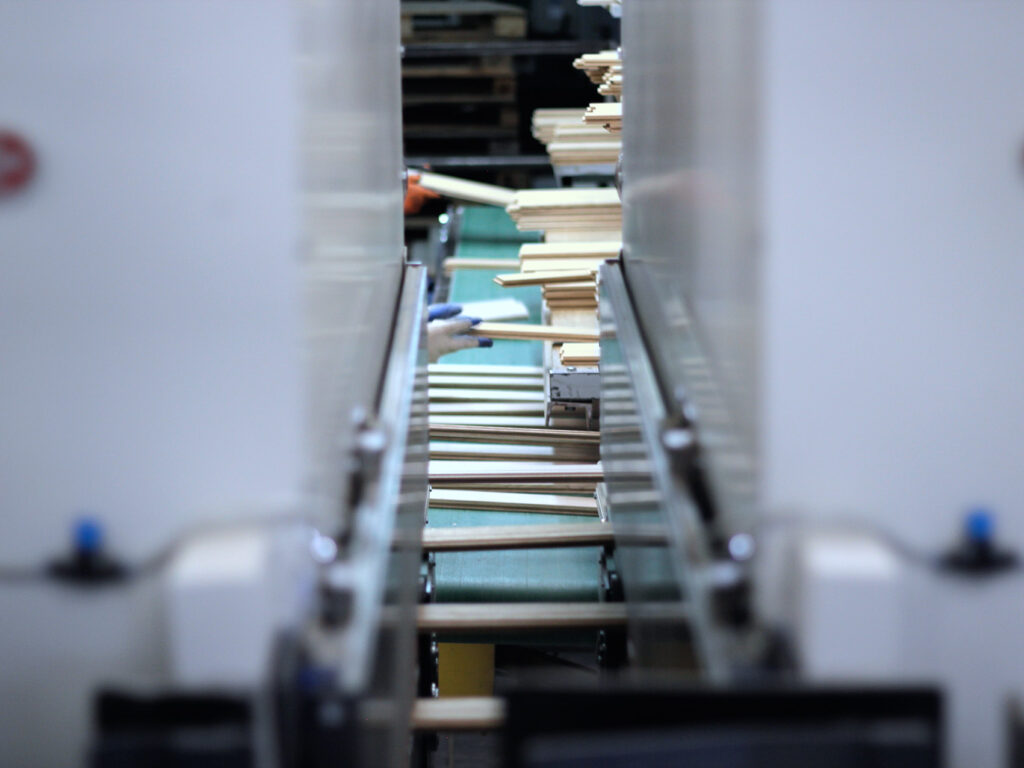

We reveal the behind-the-scenes of our production! In one of the episodes of the "Polak Potrafi" program produced by TVN Turbo, we show the entire production process - from a raw log of wood to the finished floor, covered with varnish or natural oil wax. Thanks to this, viewers can see how our product is created step by step, which combines traditional craftsmanship with modern technologies.

We reveal the behind-the-scenes of our production! In one of the episodes of the "Polak Potrafi" program produced by TVN Turbo, we show the entire production process - from a raw log of wood to the finished floor, covered with varnish or natural oil wax. Thanks to this, viewers can see how our product is created step by step, which combines traditional craftsmanship with modern technologies.